2022 Kawasaki KX450X Valve Clearance

Valve Clearance

Valve and valve seat wear decreases valve clearance, upset valve timing.

NOTICE

If the valve clearance is left unadjusted, wear will eventually cause the valves to remain partly open, which lowers performance, burns the valves and valve seats, and may cause serious engine damage.

Valve clearance for each valve should be checked and adjusted in accordance with the Periodic Maintenance Chart.

Valve clearance must be checked when the engine is cold (room temperature).

NOTE

lf the engine is hot, wait until the engine cools.

Valve Clearance Inspection

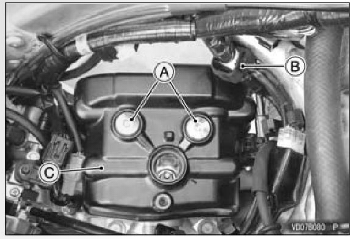

- Remove the spark plug cap (see Spark Plug section).

- Remove the cylinder head cover bolts and washers.

- If necessary open the clamp, and remove the cylinder head cover.

A. Cylinder Head Cover Bolts and Washers

B. Clamp

C. Cylinder Head Cover

- Remove the head cover gasket and spark plug hole gasket.

A. Head Cover Gasket

B. Spark Plug Hole Gasket

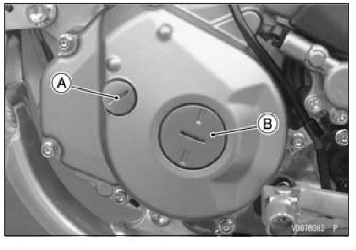

- Remove the two caps from the alternator cover.

A. Timing Inspection Cap

B. Alternator Rotor Nut Cap

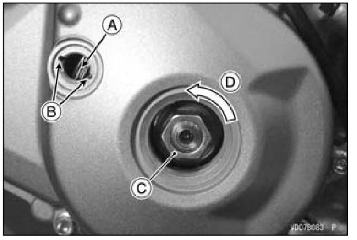

- Bring the piston to the Top Dead Center (TDC) of its compression stroke to inspect the valve clearance (the position at the end of the compression stroke) by aligning the top mark with the grooves on the alternator cover while turning the crankshaft counterclockwise.

A. Top Mark

B. Grooves on Alternator Cover

C. Crankshaft

D. Crankshaft Rotation Direction

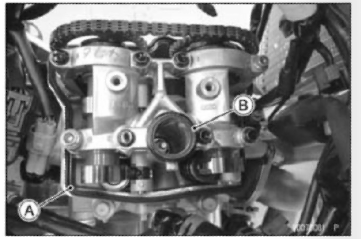

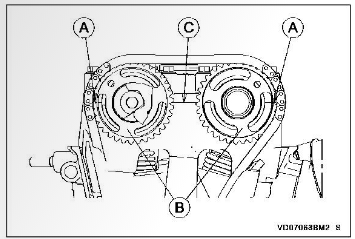

- At this point, the timing marks on the camshaft sprockets must be almost aligned with the cylinder head’s upper surface as shown.

A. Timing Marks

B. Camshaft Sprockets

C. Cylinder Head Upper Surface

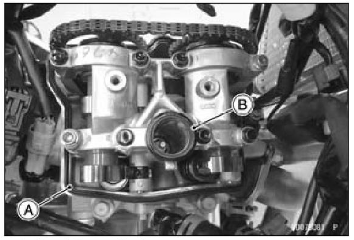

- Using the thickness gauge, measure the clearance between each cam lobe and rocker’s arm, for all four valves.

NOTE

Record the measured valve’s clearance.

A. Thickness Gauge

Standard Valve Clearance

- Exhaust 0.14 0.18 mm (0.0055 0.0071 in.)

- Intake 0.08-0.12 mm (0.00310.0047 in.)

- If the valve clearance is not within the specified range, adjust by an authorized Kawasaki dealer or a competent mechanic following the instructions in the Service Manual.

- Using a high flash-point solvent, clean off any oil or dirt that may be on the liquid gasket coating area.

- Dry them with a clean cloth.

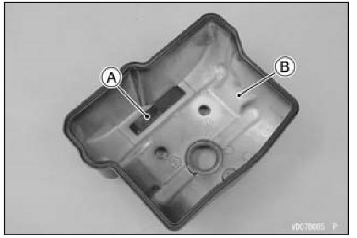

- Replace the head cover gasket with a new one.

- Install the head cover gasket on the cylinder head.

- Replace the spark plug hole gasket with a new one, and install it.

A. Head Cover Gasket

A. Head Cover Gasket

B. Spark Plug Hole Gasket

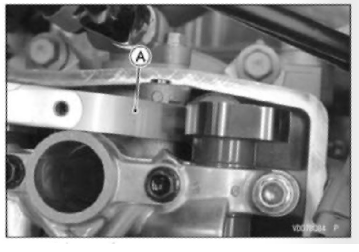

- Make sure that the upper chain guide is bottomed to the cylinder head cover.

A. Upper Chain Guide

A. Upper Chain Guide

B. Cylinder Head Cover

NOTICE

Unless the upper chain guide is bottomed, the camshaft chain could push the cylinder head cover upward, leading to an oil leak.

- Install the cylinder head cover.

- Install the washer with the metal side upwards to the cylinder head cover, and tighten its bolts to the specified torque.

- Tightening Torque_

- Cylinder Head Cover Bolts:

- 10 Nm (1.0 kgf m, 89 in-lb)

- Cylinder Head Cover Bolts:

- Install the two caps to the alternator cover

- Tightening Torque

- Timing Inspection Cap:

- 3.5 N-m (0.36 kgfm, 31 in lb)

- Alternator Rotor Nut Cap:

- 3.5 Nm (0.36 kgfm, 31 in-lb)

- Timing Inspection Cap:

- Install the removed parts.