2022 Jaguar F-TYPE Wheel Changing

WHEEL CHANGING SAFETY

Make sure to read and fully understand the following warnings. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death.

If in any doubt regarding the ability to carry out the instructions, or comply with warnings, seek assistance.

Always find a safe place to stop, off the highway and away from traffic. Switch on the hazard warning lights to alert all traffic of the obstruction. Apply the Electric Parking Brake (EPB) and engage Park (P). Switch the engine off and remove the smart key from the vehicle.

If available, place a warning triangle at a suitable distance behind the vehicle, facing toward oncoming traffic.

Different countries have different traffic laws. Carrying and/or using warning triangles may be required by law when stopping at the side of a highway. The driver is responsible for staying informed about road regulations, and for complying with local traffic laws.

In an emergency or a breakdown situation, wear a reflective jacket if stopped at the side of the road and working around the vehicle.

Different countries have different traffic laws. Carrying and/or wearing reflective jackets may be required by law. The driver is responsible for staying informed about road regulations, and for complying with local traffic laws.

Make sure that all passengers, and animals, are out of the vehicle and in a safe place, away from the highway.

Make sure that the vehicle and jack are both on firm, level ground. Do not jack the vehicle if it is over a metal grating or manhole cover.

Make sure that the front wheels are in the straight-ahead position and engage the steering lock.

Always use the complete jacking lever assembly throughout the wheel-changing process, to minimize any chance of accidental injury. Position the jack from the side of the vehicle, in line with the appropriate jacking point. Never place anything between the jack and the ground, or between the jack and the vehicle. Do not attempt to raise the vehicle, unless the jack head is fully engaged in the jacking point. Only jack the vehicle using the approved jacking points.

WARNING – THAT NO PERSON SHOULD PLACE ANY PORTION OF THEIR BODY UNDER A VEHICLE THAT IS SUPPORTED BY A JACK.

The jack is designed for wheel changing only. Never work beneath the vehicle with the jack as the only means of support. Always use correctly-rated vehicle support stands, before putting any part of the body beneath the vehicle.

Do not make any alterations or modifications to the jack.

When jacking the vehicle, make sure that all precautions are taken to prevent vehicle movement. As an additional precaution, it is recommended that the wheels of the vehicle are choked.

When one rear wheel is lifted off the ground, the transmission Park (P) position does not prevent the vehicle from moving. The vehicle can potentially slip off the jack, as the Electric Parking Brake (EPB) operates only on the rear wheels. Use a wheel chock when jacking the vehicle.

Always check the wheel diagonally opposite the wheel to be changed. Check the front of a front wheel or the rear of a rear wheel.

If jacking the vehicle on a slight slope is unavoidable, place the chocks on the downhill side of the two opposite wheels. Two chocks must be used if this is the case.

Take care when loosening the lug nuts. The lug wrench may slip off if not properly attached, and the lug nuts may give way suddenly. Either unexpected movement may cause an injury.

Do not start or run the engine while the vehicle is supported only by a jack.

Remove the spare wheel before jacking the vehicle, to avoid destabilizing the vehicle when raised. Take care when lifting the spare wheel and removing the punctured wheel. The wheels are heavy and can cause injuries if not handled correctly.

After wheel changing, always secure the tools, jack, and the replaced wheel in the correct storage positions. Such objects, if not properly stored, can become propelled objects in a crash or rollover.

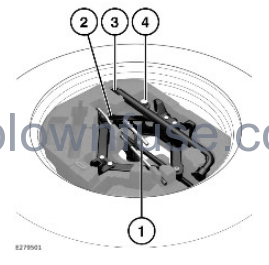

TOOL KIT

Before raising the vehicle, make sure the relevant safety warnings have been read and understood. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death.

The tool kit is located in the luggage compartment and rested on the spare wheel.

Tool types and positions may vary from the illustration.

The location of the tools is as follows:

- Spare wheel securing bolt and clamp.

- Jack: Observe the instructions printed on the jack.

- Lug wrench.

- Locking lug nut adapter.

Examine the jack occasionally. Clean and grease the moving parts, particularly the screw thread, to prevent corrosion.

Take careful note of the storage position for each tool, as it is important to return them to their correct position after use.

REMOVING THE SPARE WHEEL

Make sure to read and fully understand the following warnings. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death.

Remove the temporary-use spare wheel before jacking the vehicle, to avoid destabilizing the vehicle when raised.

Wheels are heavy and, if handled incorrectly, may cause injury. Use extreme caution when lifting or maneuvering the wheels.

Do not store the wheel while the vehicle is raised on the jack.

After wheel changing, always secure the tools, chocks, jack, and the replaced wheel in the correct storage positions. Such objects, if not properly stored, can become propelled objects in a crash or rollover, potentially causing injury or death.

Always secure the temporary-use spare wheel, or the removed wheel, in the correct position using the securing bolt.

To remove the spare wheel:

- Turn the temporary-use spare wheel securing bolt counter-clockwise until it comes free. See TOOL KIT.

- Remove the temporary-use spare wheel.

IMPORTANT – USE OF SPARE TIRE

Make sure to read and fully understand the following warnings. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death.

Adhere to the instructions on the temporary-use spare wheel’s warning label, affixed to the wheel. Failure to do so may cause vehicle instability and/or tire failure.

Where fitted, the temporary-use spare wheel is for temporary use only.

Drive with caution while the temporary-use spare wheel is fitted.

Make sure that an original size wheel and tire are fitted as soon as possible.

Do not fit more than one temporary-use spare wheel at any one time.

Do not exceed 50 mph (80 km/h) while the temporary-use spare wheel is fitted.

The temporary-use spare wheel must be inflated to 60 psi (4.2 bar, 420 kPa) and cannot be repaired.

Dynamic Stability Control (DSC) must be switched on while the temporary-use spare wheel is in use.

TracDSC must be switched off while the temporary-use spare wheel is in use.

Traction devices, such as snow chains, cannot be used with a temporary-use spare wheel.

Before removing the spare wheel, take note of its storage position. The wheel to be changed must be correctly stored and secured in its place.

USING WHEEL CHOCKS

Make sure the relevant safety warnings have been read and understood before using wheel chocks. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death. See WHEEL CHANGING SAFETY.

Wheel chocks are a useful addition to a vehicle’s tool kit. If required, a wheel chock can be stored with the vehicle’s tool kit. See TOOL KIT.

LOCKING LUG NUTS

When the vehicle is first supplied, the locking lug nut adapter may be stored in the glove box. If this is the case, move the locking lug nut adapter to its correct storage position, as soon as possible. See TOOL KIT.

Not all vehicles have locking lug nuts as standard parts.

The locking lug nut adapter must be correctly aligned and fully fitted to the locking lug nut before usage. Incorrect fitment can result in permanent damage to the locking lug nut adapter. Incorrect fitment can cause the locking lug nut’s anti-tamper device to rotate, preventing the removal of the locking lug nut. If in doubt, contact a retailer/authorized repairer.

Do not use air tools or power tools to remove or refit the locking lug nut. Doing so may damage the locking lug nut or the locking lug nut adapter.

Locking lug nuts can be removed and fitted using only the special locking lug nut adapter provided.

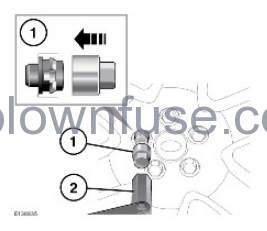

To release the locking lug nut:

- Fit the locking lug nut adapter onto the locking lug nut. Make sure that the locking lug nut adapter fully engages.

CAUTION

If the locking lug nut adapter is forced onto the locking lug nut, the adapter may be damaged beyond repair.

- Locate the lug wrench over the locking lug nut adapter. Unscrew the lug nut by half a turn counter-clockwise.

- Raise the vehicle on the jack so the wheel is off the ground.

- Remove the locking lug nut.

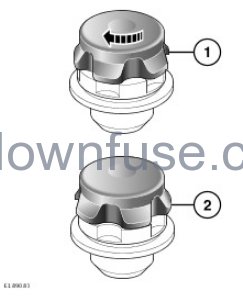

The locking lug nut and locking lug nut adapter contain two anti-tamper features.

If the locking lug nut adapter is not fully engaged, the cap on the locking lug nut rotates. To allow the locking lug nut to be fully tightened or removed, the locking lug nut cap must be reset.

The locking lug nut cap can be reset as follows:

- Carefully fit the locking lug nut adapter onto the locking lug nut cap. Rotate the cap.

- Rotate the cap until all of the grooves on the cap align exactly with the locking lug nut grooves.

Should a replacement locking lug nut adapter be required, consult an authorized retailer. It is advised to make a note of the locking lug nut adapter code number to allow a replacement to be sourced if ever required. Depending upon the specification of the locking lug nut adapter, the code may be stamped on the locking lug nut adapter or supplied on a separate card.

| Locking lug nut adapter code number |

WHEEL CHANGING

Make sure to read and fully understand the following warnings. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death.

Before raising the vehicle, refer to all warnings at the beginning of this section of the Owner’s Handbook. Failure to comply with the safety instructions could result in an accident, leading to serious injury or death. See WHEEL CHANGING SAFETY.

Remove the spare wheel before jacking the vehicle, to avoid destabilizing the vehicle when raised.

Do not attempt to raise the vehicle, unless the jack head is fully engaged in the jacking point. Only jack the vehicle using the approved jacking points.

The jack is designed for wheel changing only.

Only jack the vehicle using the jacking points described, as damage to the vehicle could occur.

Vehicles with carbon ceramic brake rotors are supplied with two-wheel guide pins. The pins are stored with the compressor in the tire repair system. Make sure that the two-wheel guide pins are used, to aid in removing and refitting road wheels on vehicles with carbon ceramic brake rotors. Failure to do so may damage the brake system. See TIRE REPAIR SYSTEM.

Before raising the vehicle, correctly position the wheel chocks. See USING WHEEL CHOCKS.

To change a wheel:

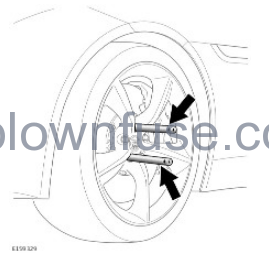

- Use the lug wrench to loosen the lug nuts of the wheel to be replaced. Turn half a turn counter-clockwise.

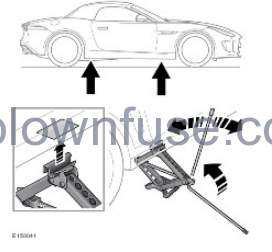

- Locate the jack under the relevant jacking point.

CAUTION

Do not allow the jack to contact the sill at any other point, as damage may result.

- Unfold the handle from the stored position on the jack. Fit the lug wrench to the end of the cranking handle.

- Rotate the handle clockwise to raise the jack, until the jack pin locates into the jacking point.

- Raise the vehicle until the wheel is clear of the ground.

- Remove the lug nuts. Place the lug nuts together where they cannot roll away.

- Remove the wheel and place it to one side.

CAUTION

Do not lay the wheel on its face, as this may damage the finish.

- Fit the spare wheel to the hub.

- Refit the lug nuts. Lightly tighten the lug nuts. Make sure the wheel is making contact with the hub evenly.

- Make sure the area under the vehicle is clear of obstructions. Lower the vehicle slowly and smoothly.

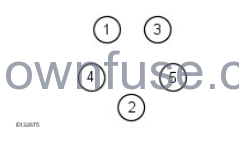

- With all of the wheels on the ground and the jack removed, fully tighten the lug nuts. Tighten the lug nuts, in the sequence shown in the illustration, to the correct torque to 92 lb.ft (125 Nm).

If it is not possible to torque the lug nuts when a wheel is replaced, set it to the correct torque as soon as possible. Failure to do so can lead to serious injury or death.

If an alloy spare wheel is to be fitted, use a suitable blunt tool to knock the center cap out of the removed wheel. Use hand pressure only to press the center cap into the newly fitted spare.

Check and adjust the tire pressure as soon as possible.

Carbon ceramic brake discs are susceptible to damage. Take care not to damage the brake discs when removing and refitting the road wheels. Vehicles with carbon ceramic brake rotors are supplied with two-wheel guide pins. The pins are stored with the compressor in the tire repair system. See TIRE REPAIR SYSTEM.

To change a wheel:

- Follow the wheel-changing procedure to step 5, until the vehicle is clear of the ground.

- Remove two opposing lug nuts and fit the two-wheel guide pins.

- Remove the remaining lug nuts. Place the lug nuts together where they cannot roll away.

- Continue the wheel-changing procedure from step 7.

Do not remove the two-wheel guide pins from the vehicle until the wheel has been lightly tightened with three lug nuts.