2022 Kawasaki KX112 Cooling System

Cooling System

Water Hoses

Check the water hoses for cracks or deterioration, and the connections for looseness in accordance with the Periodic Maintenance Chart.

Radiator

Check the radiator fins for obstruction by insects or mud. Clean off any obstructions with a low-pressure stream of water.

NOTICE

- Using high-pressure water, as from a car wash facility, could damage the radiator fins and impair the radiator’s effectiveness.

- Do not obstruct or deflect airflow by installing unauthorized accessories in front of the radiator.

- Interference with the cooling airflow can lead to overheating and consequent engine damage.

Coolant

The coolant absorbs excessive heat from the engine and transfers it to the air through the radiator. If the coolant level becomes low, the engine overheats and may suffer severe damage. Check the coolant level each day before riding the motorcycle, and replenish the coolant if the level is low.

WARNING

The cooling system can get extremely hot during normal operation and cause serious burns. Do not touch the radiator when it is hot, nor open the radiator cap. The hot coolant inside will cause severe burns.

NOTICE

Use coolant-containing corrosion inhibitors made specifically for aluminum engines and radiators in accordance with the instruction of the manufacturer. Soft or distilled water must be used with the antifreeze in the cooling system. If hard water is used in the system, it causes scale accumulation in the water passages, and considerably reduces the efficiency of the cooling system.

NOTE

The coolant originally filled into the cooling system contains 50% ofa permanent, ethylene-glycol -based antifreeze, has a freezing point of-35°C -31 F) and a green appearance.

Coolant Level Inspection

Situate the motorcycle perpendicular to the ground until the radiator cap is level with the ground so that the radiator cap is located uppermost in order to exhaust the air accumulated in the radiator.

- Remove the radiator cap.

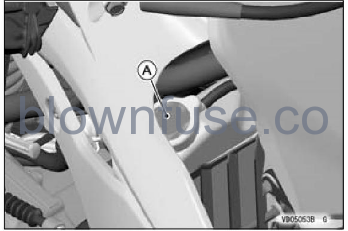

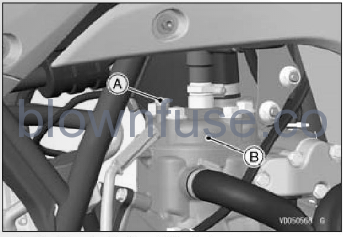

- A. Radiator Cap

Check the coolant level in the radiator.

The coolant should come up to the bottom of the radiator filler neck.

NOTE

Check the coolant level when the engine is cold (room or ambient temperature).

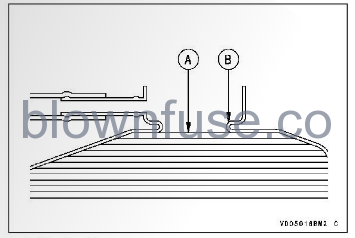

- A. Coolant Level

- B. Radiator Filler Neck

If the coolant level is low, add coolant through the radiator filler opening to the bottom of the radiator filler neck.

Recommended Coolant Mixed Ratio

- Soft water 50%, coolant 50%

Recommended Coolant Type

Permanent type of antifreeze (soft water and ethylene glycol plus corrosion and rust inhibitor chemicals for aluminum engines and radiators)

Coolant Total Amount

- 0.5 L (0.52 US qt)

- Install the radiator cap.

Coolant Change

The coolant should be changed periodically to en- sure long engine life.

- Wait for the engine to cool completely.

- Situate the motorcycle perpendicular to the ground until the radiator cap is level to the ground.

- Drain the coolant from the engine and radiator as follows.

- Place a container under the coolant drain bolts at the water pump cover and right side of the cylinder.

- Remove the radiator cap.

- Remove the coolant drain bolts and the gaskets.

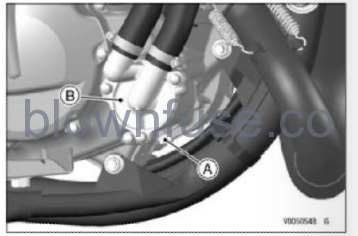

- A. Coolant Drain Bolt (Water Pump) and Gasket

- B. Water Pump Cover

- A. Coolant Drain Bolt (Cylinder) and Gasket

- B. Right Side of the Cylinder

NOTICE

Immediately wash away any coolant that spills on the frame, engine, or wheel.

WARNING

Coolant on tires will make them slippery and can cause loss of traction resulting in an accident and injury. any coolant that might have splashed on the tires.

- Visually inspect the old coolant.

- If whitish cotton-like wafts are observed, aluminum parts in the cooling system are corroded and the system must be flushed.

- If the coolant is brown, iron or steel parts are rusting and the system must be flushed.

- Check the cooling system for damage, loose connections, and leaks.

- Install the coolant drain bolts with their new gaskets at the water pump cover and right side of the cylinder.

NOTE

Always replace gaskets with new ones. Tighten the coolant drain bolts to the specified torque.

Tightening Torque

Coolant Drain Bolt (Water Pump): 5.2 Nm (0.53 kgfm, 46 in lb)

Coolant Drain Bolt (Cylinder): 9.0 N-m (0.92 kgfm, 80 in-lb)

NOTE

Pour in the coolant slowly so that it can expel the air from the engine and radiator.

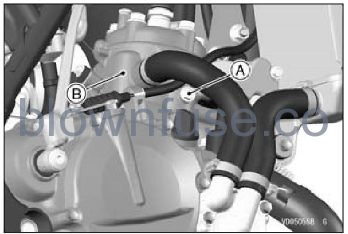

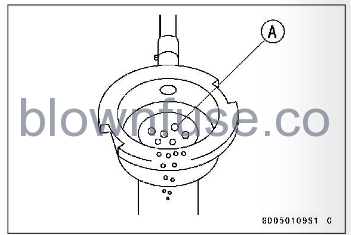

- A. Air Bleeder Bolt and Gasket

- B. Cylinder Head

Tightening Torque

Air Bleeder Bolt: L 10 Nm (1.0 kgfm, 89 in-lb)

- If the coolant level is low, add coolant up to the bottom of the radiator filler neck.

- Tap the water hoses to force out any air bubbles caught inside.

- Tighten the air bleeder bolt to the specified torque.

- A. Air Bubbles

- Check the coolant level (see Coolant Level Inspection in this section).

- If the coolant level is low, add coolant up to the bottom of radiator filler neck.

- Install the radiator cap.

- Start the engine and warm up thoroughly, then stop it.

- Check the coolant level after the engine has cooled down.

- If the coolant level is low, add coolant up to the bottom of the radiator filler neck.

- Install the radiator cap.

- Check the cooling system for leaks.