2022 Kawasaki KLX300R Drive Chain

Drive Chain

For safety and to prevent excessive wear, the drive chain must be checked, adjusted, and lubricated before riding. If the chain becomes badly worn or maladjusted- either too loose or too tight- it could jump off the sprockets or break.

WARNING

A chain that breaks or jumps off the sprockets could snag on the engine sprocket or lock the rear wheel, severely damaging the motorcycle and causing it to go out of control. In spect the chain for damage and proper adjustment before each ride.

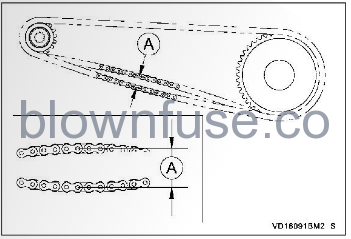

Chain Slack Inspection

- Raise the rear wheel off the ground using a suitable stand.

- Rotate the rear wheel to find the position where the chain is tightest and measure the maximum chain slack by puling up and pushing down the chain midway between the engine sprocket and rear wheel sprocket.

Drive Chain Slack

Standard 30 40 mm (1.2-1.6 in.) Adjust the drive chain if its slack is out of specification

A. Chain Slack

- In addition to checking the slack, rotate the rear wheel to inspect the drive chain for damaged rollers, loose pins and links, and the sprockets for unevenly or excessively worn and damaged teeth

- If there are any such defects, replace the drive chain and/or the sprockets.

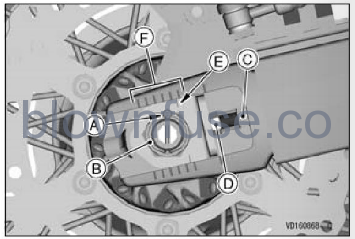

Chain Slack Adjustment

- Remove the cotter pin from the rear axle.

- Loosen the rear axle nut and both chain adjuster locknuts.

- Turn both chain adjusting bolts evenly until obtaining the standard chain slack. To keep the chain and wheel properly aligned, the notch on the indicator plate should be aligned with the same scale reading on both sides.

Drive Chain Slack

30-40 mm (1.2- 1.6 in.)

A. Cotter Pin

B. Axle Nut

C. Locknut

D. Adjusting Bolt

E. Notch

F. Scale Mark

NOTE

Wheel alignment can also be checked using the straightedge or string method.

WARNING

Misalignment of the wheel will result in abnormal wear, and may result in an unsafe riding condition. Align the rear wheel using the marks on the swingarm or measure the distance between the center of the axle and the swingarm pivot.

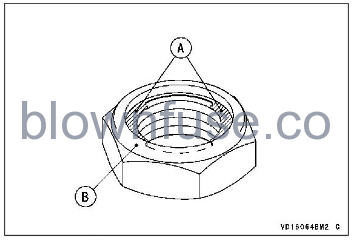

Visually inspect the rear axle nut for deformation or damage at the friction ring and caulking. If it is deformed or damaged, replace the axle nut with a new one.

A. Friction Ring

B. Caulking

- Tighten both chain adjuster locknuts.

- Hold the axle so that its hole for the cotter pin faced vertically and tighten the rear axle nut to the specified torque.

Tightening Torque

Rear Axle Nut: L110 Nm (11.2 kgf-m, 81 ft-lb)

- Rotate the wheel, measure the chain slack again at the tightest position, and readjust it if necessary.

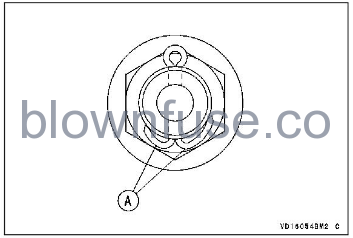

- Insert a new cotter pin through the axle from the top and spread its ends.

A. Cotter Pin

WARNING

A loose axle nut can lead to an accident resulting in serious injury or death. Tighten the axle nut to the proper torque and install a new cotter pin. Check the rear brake effect.

Chain Wear Inspection

When the chain has reached its wear limit (i.e., when it has stretched by 0.5% of its original length), it is no longer safe for use and should be replaced. Since it is impractical to measure the entire length of the chain, determine the degree of wear by measuring a 20-link section of the chain.

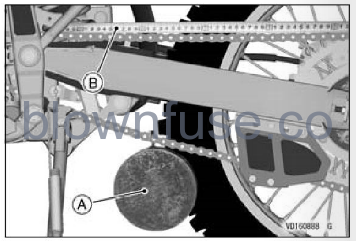

- Tighten the chain either by using the chain adjusters or by hanging 10 kg (22 Ib) weight on the chain.

- Measure the 20-link length on a straight part of the chain from the center of the 1st pin to the center of the 21st pin. If the length exceeds the service limit, the chain should be replaced. Since overworn sprockets will cause a new chain to wear faster, inspect both the engine and rear sprockets whenever the chain is replaced, and replace them if necessary.

A. Weight

B. Tape Measure

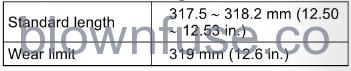

Drive Chain 20-Link Length

Chain Guide and Slipper Wear Inspection

Visually inspect the drive chain guide and replace it if excessively worn or damaged.

A. Chain Guide

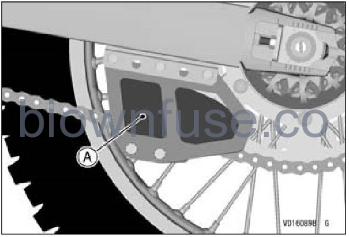

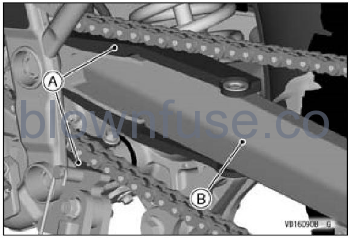

Visually inspect the chain slippers on the swingarm and replace them if worn or damaged.

A. Chain Slippers

B. Swingarm

Sprocket Wear Inspection

Visually inspect the sprocket teeth and replace the sprocket if its teeth are worn or damaged.

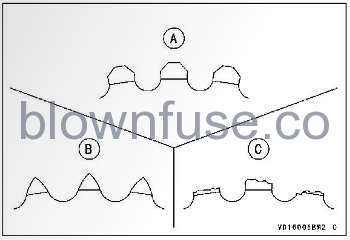

A. Good Teeth

B. Worn Teeth

C. Damaged Teeth

NOTE

Sprocket wear is exaggerated in the illustration.

Chain Lubrication

Lubrication is necessary after riding through rain or on wet roads, or any time that the chain appears dry. Use a lubricant for sealed chains to prevent deterioration of chain seals. If the chain is especially dirty, clean it using a cleaner for sealed chains following the instructions supplied by the chain cleaner manufacturer.

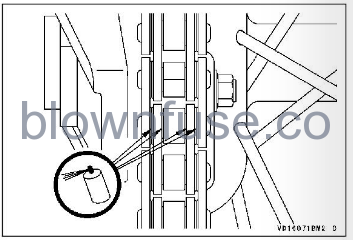

- Apply lubricant to the sides of the rollers so that it will penetrate the rollers and bushings. Apply lubricant to the seals so that the seals will be coated with lubricant.

- Wipe off any excess lubricant.